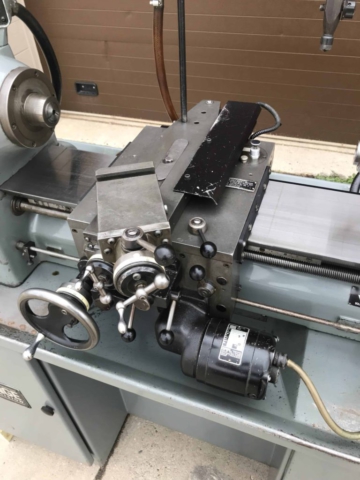

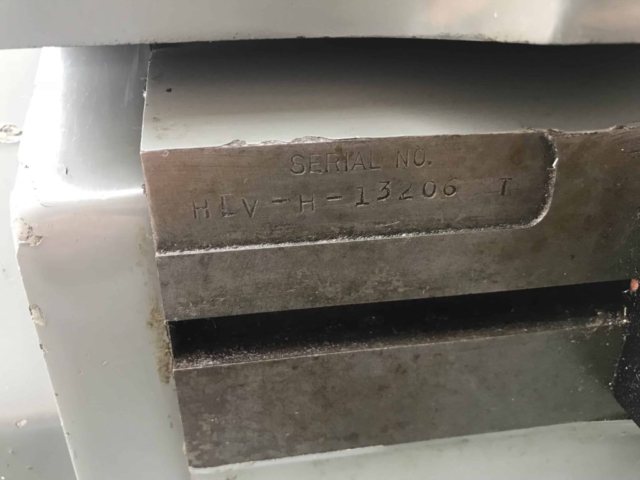

Up for sale is this Hardinge HLV-H EM (English/Metric) Super Precision Tool Room Lathe. This is in very good condition and has never been repainted. This was ordered from the factory in Hardinge white and grey colors. I purchased this machine at auction from a closed machine shop and have done a considerable amount of work to get the machine to where it is today.

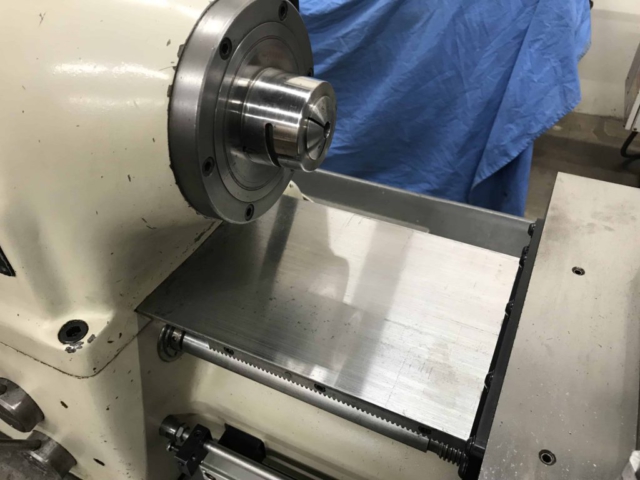

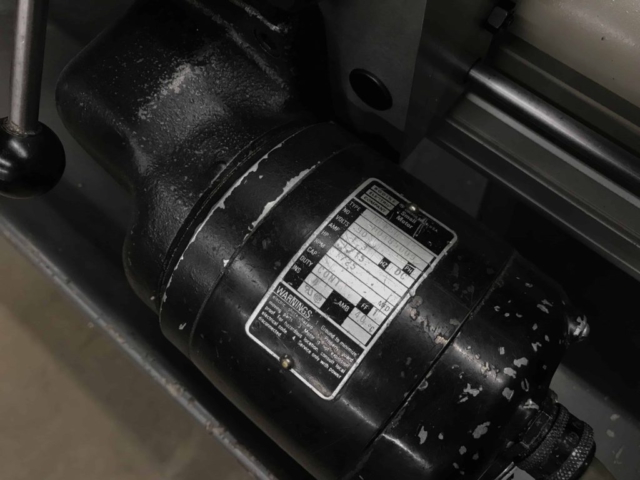

This is a late 1988 machine and it has many late model features such as hardened and ground cross slide ways, tapered Hardinge spindle, wide bed plate with teflon lined carriage, pre-drilled DRO mounting points, ball bearing carriage rack gear and more. This machine is 230V 3 Phase but it is dual voltage so it can be changed to 460V if desired.

When received, the left cross slide wear strip was delaminating from the cast iron lathe carriage (common problem) and causing unacceptable binding in the cross slide. The carriage was removed and disassembled and both wear strips were peeled off. The surfaces were prepared using factory procedures and the strips were epoxied back into place. Both the hardened wear strips and dovetail surfaces were then ground in situ. The cross slide & gib were then hand scraped and fitted to the machine. As I was doing this work I elected to have many of the carriage surfaces reground for aesthetic purposes in addition to fully cleaning the machine. The Teflon sheet on the bottom of the carriage was in good condition and so it was left untouched. The Bijur oil pump has been completely rebuilt with new o-rings, filters, and gaskets and all oil metering units, o-rings, and copper tubes have been replaced with new. New neoprene way wipers have been installed and the apron hand wheel bushings have been replaced. Both variable speed drive belts have been replaced and the V.S. countershaft bearings have been replaced as well. Lastly, the dual dial compound has been disassembled, cleaned, & lubricated. I’m sure there are other things I’m missing but that is the general overview of what I have done to this machine.

After all this work the machine is now in excellent mechanical condition and is ready to be used right away. The spindle is whisper quiet and runs great at all speeds and the power feeds work great in all speeds and directions. The machine is very clean and tight and it now looks great too. Lathe comes with pictured tooling. This has a factory installed Acu-Rite DRO as well as a factory work light. Other accessories are available such as taper attachment, follow rest, steady rest, chucks, tool post, etc.

SPECIFICATIONS:

Spindle Capacity 5C Collets – Round……………………………..1-1/16″

Spindle Capacity 5C Collets – Hex……………………………………..7/8″

Spindle Capacity 5C Collets – Square…………………………………3/4″

Step Chucks…………………………………………………………1-1/16″ – 6″

Spindle Nose………………………………………………Hardinge Tapered

Variable Spindle Speeds…………………………………125 – 3000 RPM

Swing Over Bed……………………………………………………………….11″

Swing Over Cross Slide………………………………………………………6″

Swing Over Carriage…………………………………………………………..9″

Distance Between Centers…………………………………………………18″

Hole thru Spindle………………………………………………………….1-1/4″

Compound Slide Travel………………………………………………………3″

Carriage Power Feed Range……………………………….5/16″ – 7 IPM

Cross Slide Power Feed Range……………………………3/16″ – 4 IPM

Tailstock Spindle Travel…………………………………………………3-3/4″

Tailstock Spindle Taper…………………………………………….No. 2 MT

Lead Screw Diameter…………………………………………1″ – 8 Thread

Range of Threads in Gear Box……………………………………11 – 108

Number of Thread Changes in Gear Box……………………………..72

Inch Threading……………………………………………..(36) 11 – 108 TPI

Metric Threading…………………………………….(35) 0.4375 – 2.7 mm

Electrics………………………………………………………..230V/3Ph/60Hz

*Preliminary Specifications Subject to Verification.

SOLD